Methyl Ethyl Keton Peroxide (MEKP). 50% soluation in Plasticizer with low peroxide based. Cololursless liquid, light viscose liquid Polyester Hardener A to catalyst the Resin.

srpolychem@yahoo.com

srpolychem@yahoo.com

We started our activity as SSI unit in 2005. We are the manufacturer of ancillaries chemicals for FRP industries Viz. Catalyst(MEKP-50%), Accelerator, PVA (Releasing Agent) and Polymer Solvent (Cleaning Agent) to suit the customer requirement and being serve the same in the field of FRP industries since 1995 as well as Concrete cement based Industries for their coating and chemicals for the Designer concrete tile. We manufacturer and market the COMPOSITE RAW MATERIAL. And all kind of technologies develop in-house with better control on all aspect of production with expert for the development of Polyester Hardener-MEKP and ancillaries chemicals. Source the reliable materials and metalizing the Idea to meet the requirement of FRP Industries. We are the team of expert and Idea provider for the material in Composites Industries and the service oriented for the prompt supply for the requirement at the door step service with our customer to meet their catalyst to catalyst the requirement.

It is highly recommend for CEMENT CONCRETE TILE INDUSTRIES and other like, Well ring, Railway tracking slab, building construction for leak proof to reduce the porosity in RCC roof and many more where being used this coating chemicals even if interior and exterior decors.

Tile manufacturer in India, exclusive in Gujrat and all around the country and abroad. To approach the material with builder for the purpose of prevent leakage the water in RCC roof, joint and pillar to reduce the porosity.

GP is an unsaturated general purpose polyester resin produced for the manufacture of General Purpose Fibre Glass all general moulding for various type. NTP 101 is medium viscosity resin to wet the fibre glass horizontal as well as vertical.

FRP – Fibre Reinforced Plastic Or Polymers

Lack of catalyst and accelerator Very low temperature Damp filler used or mould Excessive amount of pigment

Damp mouldDamp brush to apply gel coat Mixing of catalyst not regularPVA agent undrive on mould

Not enough catalyst or accelerator Evaporation of styrene Damp mould Unsuitable PVA

Small air trapped in resinsDust or dust in resins or brush, viscosity of gel coat very high Enough filler or gel coat too thin Hot air blowing in Gel coat

Methyl Ethyl Keton Peroxide (MEKP). 50% soluation in Plasticizer with low peroxide based. Cololursless liquid, light viscose liquid Polyester Hardener A to catalyst the Resin.

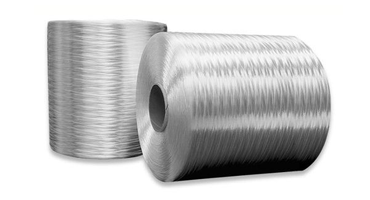

Direct roving of various linear density or tex as per the requirement of filament winding and Pultrusion.

GSM of 30 to 50 for 1040 mm width of 300 mtrs in roll. High wet out for the any type of shape to get the smooth surface.